Best manufacturers of bass guitar strings

Disclosure: Some of the links at this website could be affiliate links. This means that, at zero cost to you, I will earn an affiliate commission if you click through the link and finalize a purchase.

All bass players, without exception, face the problem of choosing bass guitar strings. That is especially true for beginning musicians who have only recently begun to master the instrument. They want the strings to sound good, hold their shape longer, and be comfortable to play. Their more experienced colleagues would probably suggest the factors influencing the correct choice: the required thickness, material of manufacture, and type of winding. But even if you once choose the most suitable strings, it turns out over time that you can find better options. Manufacturers are constantly improving their technology using various innovative approaches. I’ll briefly tell you about five TOP companies whose products are popular among the world’s leading bass players.

| Brand | Rating | Price | Link |

|---|---|---|---|

| ➤ Ernie Ball Regular Slinky Nickel Wound | ★ 4.8 | ~18$ | BUY |

| ➤ Ernie Ball 2833 Hybrid Slinky Round Wound | ★ 4.7 | ~17$ | BUY |

| ➤ D’Addario Bass Guitar Strings NYXL 45-100 | ★ 4.7 | ~30$ | BUY |

| ➤ XL Nickel Bass Strings – EXL170 | ★ 4.8 | ~15$ | BUY |

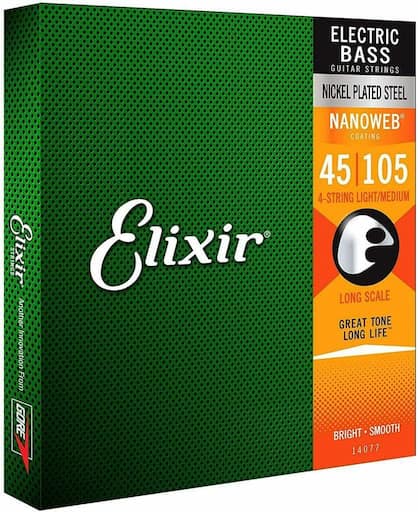

| ➤ Elixir Strings Nickel Plated Steel 4-String (NANOWEB Coating) | ★ 4.7 | ~44$ | BUY |

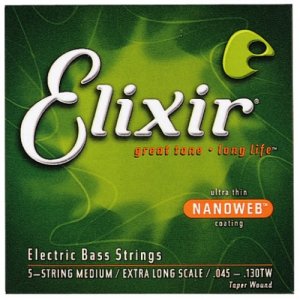

| ➤ Elixir Stainless Steel 5-String Bass Strings set | ★ 4.7 | ~50$ | BUY |

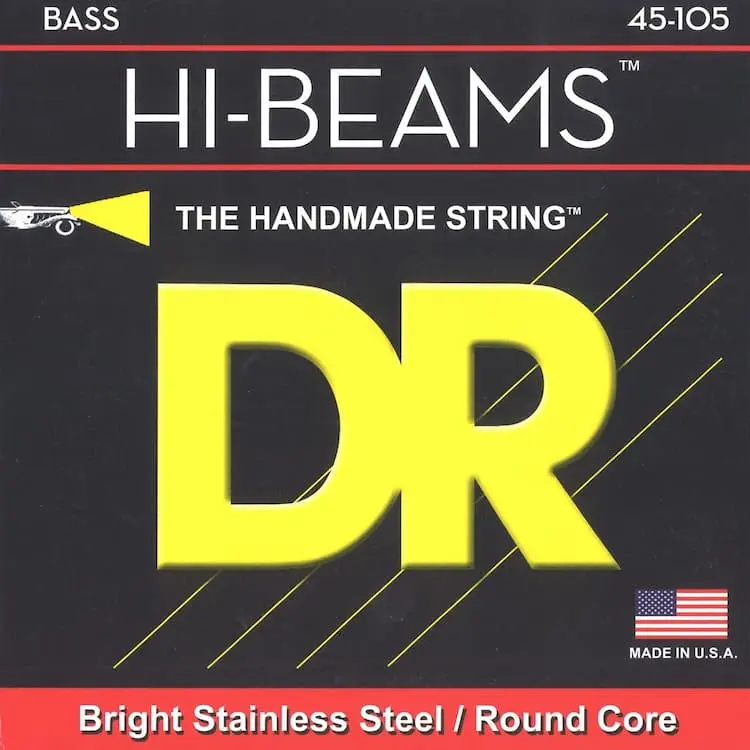

| ➤ DR HI-BEAMS – Stainless Steel, 45-105, Round Core | ★ 4.7 | ~24$ | BUY |

| ➤ DR Black Beauties – Black Coated Bass Guitar Strings 45-105 | ★ 4.7 | ~24$ | BUY |

| ➤ La Bella 760FS Deep Talkin’ Bass (flat wounded) | ★ 4.8 | ~46$ | BUY |

| ➤ La Bella LTF-4A Low Tension Flats | ★ 4.7 | ~46$ | BUY |

Ernie Ball

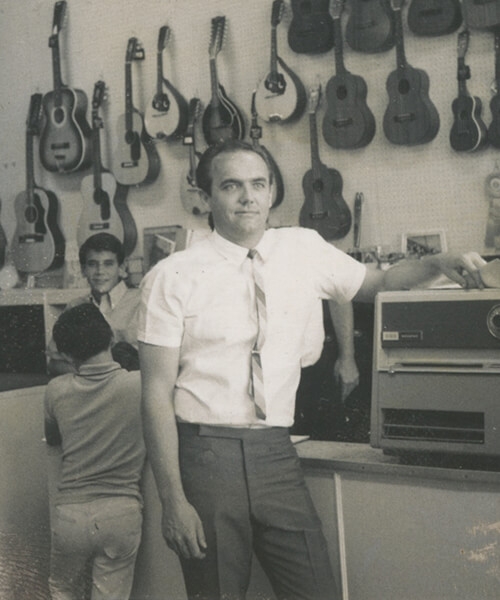

Ernie Ball is one of the most popular brands in the guitar world. The founder of the company was a professional guitarist. He worked with bands in pubs and toured with famous groups throughout the United States and across the globe. He made his first serious money on television. In the 1950s, they invited Ernie Ball to take part in creating Western Varieties. Thanks to the TV show, the musician received universal recognition and even took up teaching. At that time, he had the idea to create a company that would produce guitars and everything needed to make them sound.

Brand History

The brand history began with the opening of a small music store in Tarzana (California). That happened in 1957 or 1958, and, as Ernie assured, it was the first market in the country selling exclusively guitars. Although repeatedly criticized for refusing to sell other music equipment, Ball was adamant. He said: “I just want to sell guitars.” Two years later, he opened stores in Canoga Park and Thousand Oaks. As it turned out, guitar products were in high demand.

In 1972, Ernie collaborated with former Fender employee George Fullerton to develop the first modern acoustic-electric bass guitar, the Earthwood. Currently, these instruments are collector’s items.

Ball made its first custom strings in the early 1960s. The music world is not as big as it seems. Therefore, information about the manufacturer spread almost instantly. By the mid-1970s, the company’s products were available throughout Europe and Asia. Ball created a distribution network connecting 70 cities around the world.

In 1984, Ball purchased the Music Man Company and began producing high-quality guitars, bass guitars, and amplifiers. He moved his business to San Luis Obispo. The capacity of the new industrial site was sufficient until 2003, but the volumes increased so much that Ball had to move string production into a separate enterprise. The factory started in Coachella, southern California, and still supplies bass guitar strings to many stores across the globe. Ernie Ball died in 2004, leaving his business to his four sons.

Technological Secrets

Ernie Ball bass guitar strings remain the standard of quality. Ernie’s experiments became the basis for the invention of new technologies and their introduction into production. It mainly concerns unique alloys, including Slinky Cobalt, which gives the sound power and purity; M-Steel, which allows you to extract the loudest sounds; and Paradigm, which has increased durability.

The staff of the company’s laboratory invented a unique composition for packing guitar strings, which prevented their oxidation during transportation and ensured safe storage during operation. The idea was to completely seal the package with the help of the corrugated edge. You can use such packaging to store strings for years without being afraid they will become dirty or subject to corrosion.

Ernie Ball Regular Slinky Nickel Wound

- 50-105 Gauge

- Played by legendary bands around the world including Tool, Rage Against the Machine, Zac Brown Band, Green Day, and Avenged Sevenfold

- Element Shield Packaging prolongs string life and keeps strings as fresh as the day they were made

- Made in California, USA with the freshest and finest materials

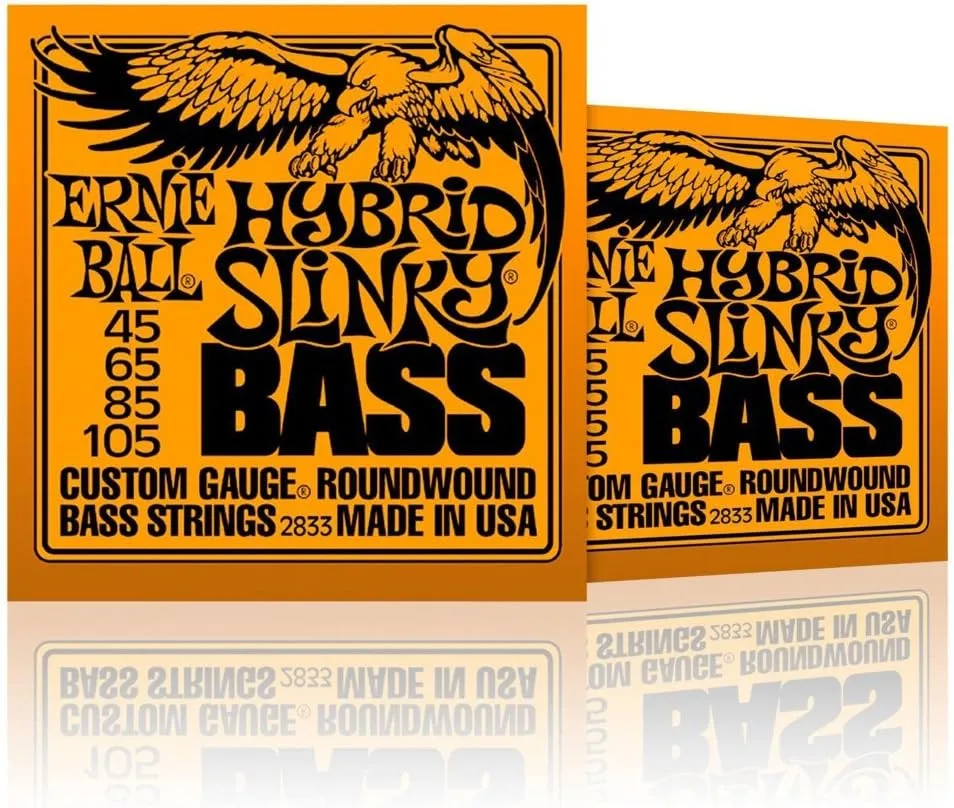

Ernie Ball 2833 Hybrid Slinky Round Wound Bass

- Hybrid Slinky’s 45-to-105 gauge is one of the most popular 4-string bass gauges

- Made in California, USA with the freshest and finest materials

- Rich, balanced tone

Bass Players Using Ernie Ball Products

Many famous guitarists, such as Bonnie Raitt, prefer Ernie Ball products. John Entwistle and Brian Ritchie played the first Earthwood basses. Brian Ball, the company’s CEO since 2019, took a personal part in developing signature bass models for Tim Commerford and Joe Dart. Most recently, he led the project to create the DarkRay bass guitar with built-in distortion, equalizer, and preamp.

Today, the company produces signature instruments for Mike Herrera, John Myung, and Cliff Williams, as well as four- and five-string Bongo, Sterling, and StingRay basses, which are in constant demand across the globe.

Directed by Brian Ball, the enterprise continues to be a leader in developing string technology. Other family members work with him. For example, his brother Scott is the company’s vice president and controls the work of all factories. This family business continues to develop thanks to the concept laid down by its founder, Ernie Ball.

D’Addario

The D’Addario brand is the leader in the export of strings and musical accessories. They send products to 101 countries around the world. Their headquarters is in Long Island, New York. The company also has offices in Brooklyn and Newcastle. D’Addario has representative offices in Canada, England, France, Italy, Germany, Australia, and China. This holding produces a wide range of products.

D’Addario Birth and Development

The history of the world-famous company began in the small Italian town of Salle, where Donato D’Addario’s family lived since the Middle Ages. They were engaged in making thin strings from pig and sheep intestines. It was a labor-intensive process that brought good income. The product was in demand among musicians of any rank, from elite court orchestra players to street wandering lutenists. The company started its activity in 1680.

In 1915, a powerful earthquake destroyed the town. Part of the family remained in Salle and continued to make strings, and two brothers, Rocco and Carmine, moved to the USA to expand the market. They settled in Queens, New York, where they opened a small store. Rocco returned to Italy three years later, but Carmine stayed in the USA. He changed his Italian name and began accepting custom orders from clients to make strings. His new name was Charles.

Charles quickly took stock of the situation and found that guitar strings were in high demand. The guitar came into fashion at the beginning of the 20th century with the advent of jazz. By the 1930s, the D’Addario family had become a guitar string manufacturer, fulfilling orders from musicians and string companies.

For more than half a century, they continued to sell their goods on behalf of other manufacturers. By the 1970s, the demand was so great the family decided to start a company. And in 1974, J. D’Addario & Company was born. They developed a marketing strategy to promote their products and invited many famous musicians to participate in it. The brand is still a family business with 13 family members involved.

The Secret of a Successful Business

The impetus for changing technology in the production of strings was the development of nylon. The D’Addario family received samples of the material from DuPont in 1947 and immediately began developing a new product. Nylon-coated strings provided a soft sound and became in demand among reggae and jazz performers. Their disadvantage was that they were not durable, so some family members wanted to expand the business by producing steel models, but Charles refused. He decided not to risk the family trend. It wasn’t until 1956 that his son John began manufacturing steel strings and created his own company, Archaic Musical String Mfg Co.

A breakthrough in the family business was the merger of D’Addario with Archaic Musical String Mfg Co. in 1974. The company developed numerous innovative products, including the first round wound bass strings. XL Nickel Double Ball End Electric, Black Nylon Tape Wound, and EXP Acoustic Bass remain popular today.

“D’Addario bass guitar strings deliver the finest low-end tone, no matter what style you play. From silky smooth Tapewounds to the bright, powerful tone of ProSteels, we’ve got bass strings for every player,” the creators of the corporation said.

D’Addario NYXL Bass Strings

- Premium uncoated bass string, delivering unrivaled strength and tuning stability, plus enhanced tonal response.

- Stay in tune better and offer greater break strength than standard bass strings.

- Made in the USA—drawn to our exacting specifications at New York production facility.

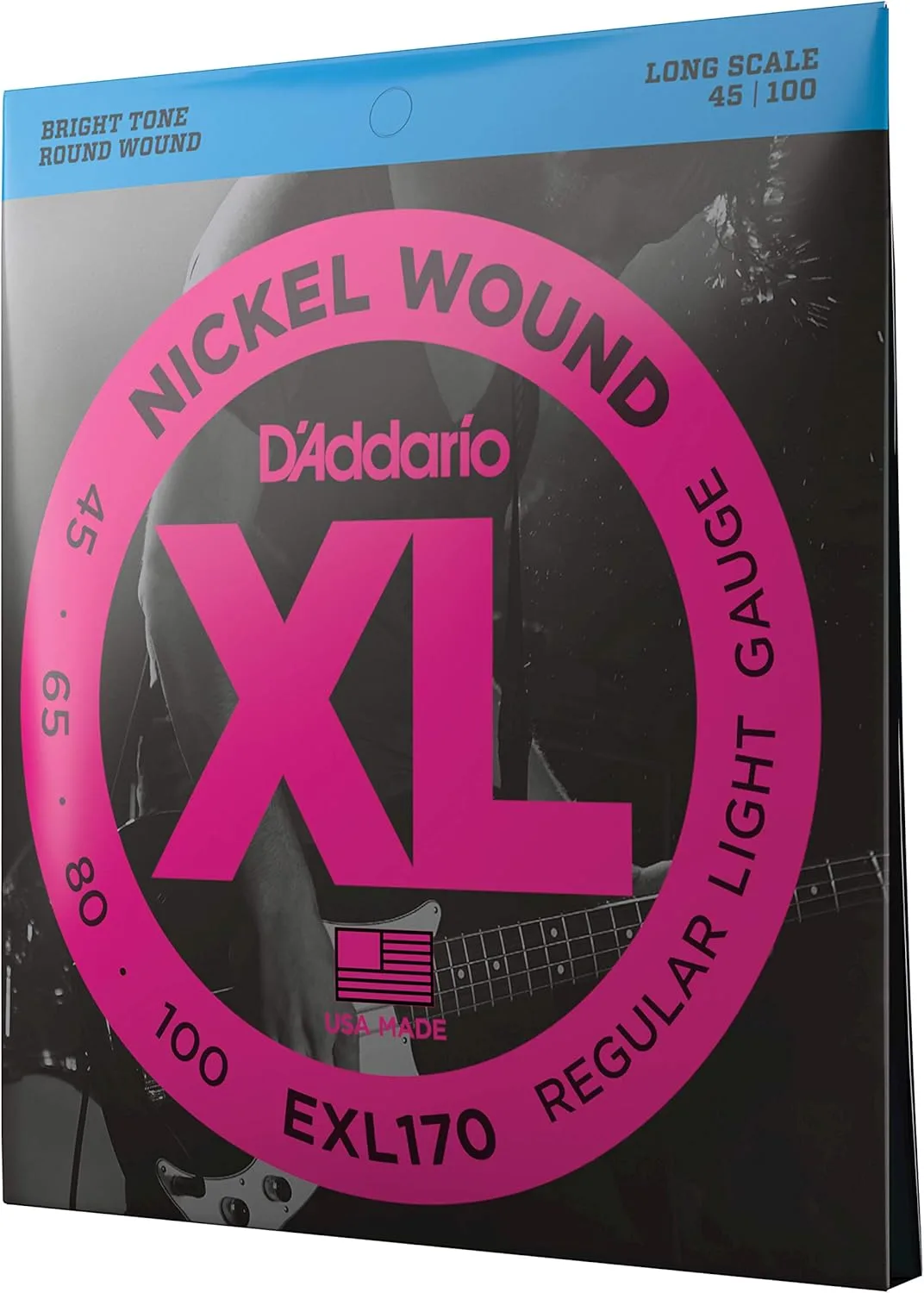

XL Nickel Bass Strings – EXL170

- TIGHT, BRIGHT TONE – Nickel-plated steel wrap wire provides a bright, tight bass sound, great for a variety of musical genres.

- XL Nickel are made with our proprietary Hex-Core, ensuring perfect intonation, consistent feel, and powerful durability.

- Best-selling electric bass strings, revered by players for their reliable performance and versatile tone.

Which Famous Bass Players Use D’Addario Products?

- Oteil Burbridge, an American multi-instrumentalist who rose to fame playing bass during the resurgence of The Allman Brothers Band from 1997 through 2014 and as a founding member of the band Dead & Company, uses EXL160 Nickel Wound Bass.

- Wolfgang Van Halen, son of Eddie Van Halen, multi-instrumentalist, leader of the band Mammoth WVH, believes that D’Addario strings help him get the sound he needs.

- Rudy Sarzo, Quiet Riot bassist who also worked with Ozzy Osbourne, Dio, Yngwie Malmsteen, Alice Cooper, Tony MacAlpine, Whitesnake, and Blue Öyster Cult, prefers strings from the D’Addario XL series. Becky Baldwin, MERCYFUL FATE bassist, uses D’Addario XL ProSteels.

Elixir

“When you get your guitar out of the case, the strings still feel fresh even after it’s been sitting there. I just like how long Elixir Strings last. I recommend them to everyone.” – American musician Marcus King about Elixir strings.

Brand History

The history of Elixir began in 1958 when Wilbert Lee Gore and his wife Genevieve Walton founded a private business producing goods from polymers. Previously, Bill spent 16 years with DuPont in various technical positions. The man decided to open his company after several years spent in the company’s laboratory, where he studied fluoropolymers. Wilbert Lee created his base for experiments in the basement of his house, where he invented a multi-core ribbon cable. Multi-Tet cable is still part of process equipment, communications, and computers.

The couple’s son, Bob Gore, purposefully studied to become a chemist at the University of Minnesota and even received a doctorate in chemical engineering. In 1963, he joined the family company. He and his father received prestigious awards for their achievements, and Bob became an inductee of the National Inventors Hall of Fame in 2006. He invented the polytetrafluoroethylene-based ePTFE polymer used today to coat guitar strings.

In 1997, the family launched a separate production of strings and cables for musical equipment. The company was named Elixir. Currently, its products are in great demand among musicians from all over the world due to their unique coating. Resistant to dust, dirt, sweat, grease, and oxidation, these strings can last much longer.

Technology

The production of the innovative material for covering bass strings uses Nanoweb technology. The fact is that a thin layer of polymer composition extends the service life by 3-5 times. At the same time, the number of overtones is reduced due to soft contact with the string while maintaining the familiar sound of a bass guitar. The most popular models are Nickel Plated Steel and Stainless Steel.

Elixir Strings Nickel Plated Steel with NANOWEB Coating

- Electric bass guitar strings constructed with nickel-plated steel wrap wire.

- Played for a rich, rounded tone with incredible clarity and a heavy mid-range presence.

- Patented coating technology protects against common corrosion, extending tone life longer than any other brand’s coated or uncoated strings.

Elixir Stainless Steel 5-String Bass Strings set

- Long Scale, 5-String Light gauge: .045 .065 .085 .105 .130

- Played for a fresh evolution of stainless tone that’s bright (but not shrill) with deep lows.

- Ultra-thin NANOWEB Coating, redesigned specifically for bass guitars, provides a smooth, natural feel that also enhances grip.

Which Famous Bass Players Prefer Elixir Strings?

- Tiffany Lloyd, an American gospel and contemporary Christian bassist, uses Electric Bass Nickel Plated Steel with NANOWEB technology.

- Armin Alic, a bass player from Germany, a seasonal musician, and a regular member of the band of German blues guitarist and singer Henrik Freischlader, uses Electric Bass Stainless Steel.

- Michael Mondesir, an English jazz bass player, prefers Electric Bass Nickel Plated Steel with NANOWEB Coating.

- Hussain Jiffry, a Sri Lankan-American bassist who performed on Herb Alpert’s Steppin’ Out and won Best Pop Instrumental Album at the 56th Grammy Awards in 2014, uses Electric Bass Stainless Steel with NANOWEB Coating.

DR

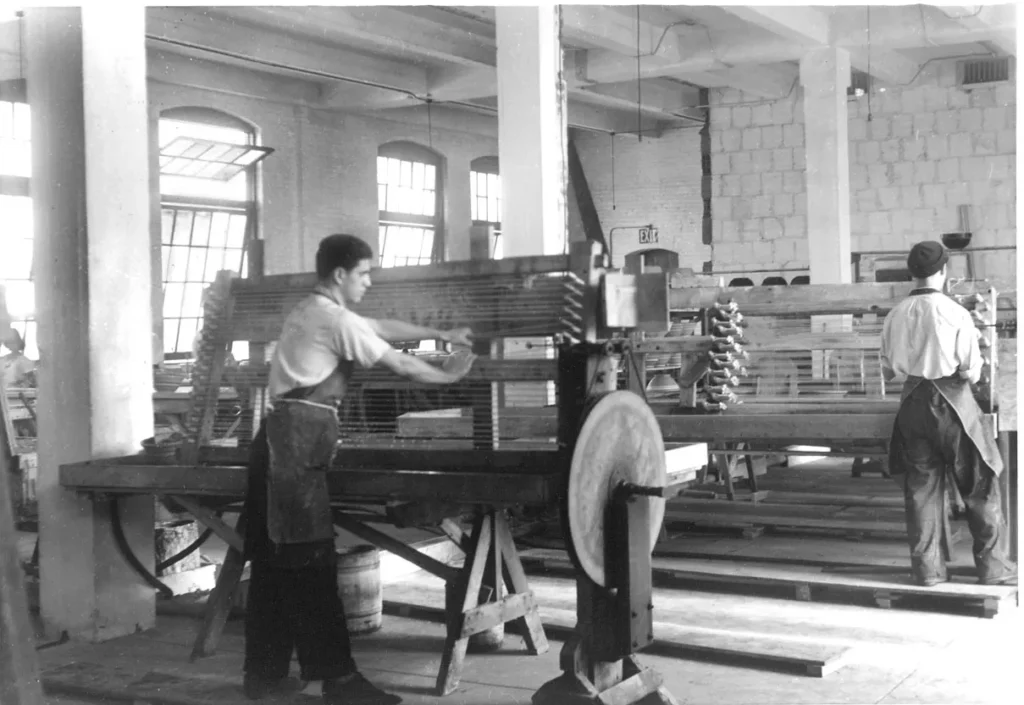

This company represents a wide range of guitar strings on the world market and still makes them the old-fashioned way – by hand. Therefore, when competitors automated their string production, the founder of DR Strings, Mark Dronge, still adhered to the “old school” concept. There are no computer-controlled machines in his factories, and his qualified specialists personally control the winding of the turns of each string. This fact increases the production time of these products and makes them more expensive than analogs from other brands.

History and Technology of DR Strings

Mark Dronge, founder of DR Strings, came from a family whose four generations were engaged in selling musical instruments. Dronge’s father sold his small store in 1948 and opened his first factory in 1952 to produce acoustic guitars. The company’s name was Guild Guitar Company. Mark began working in his father’s business at the age of 14.

He applied his experience in his guitar string manufacturing company, which he opened in 1989. His wife, Gun Elizabeth Levin, helped him with that. In 1900, her ancestor, Herman Carlson Levin, founded the largest Scandinavian company that produced various stringed instruments. Levin is known for developing the Goya acoustic guitar. The experience gained over decades was enough for the couple to launch their own business. Mark Dronge died on May 11, 2022, passing on the family business to his daughters Annika and Camilla, who continued the work started by their parents.

The company has developed a unique technology for protecting strings from corrosion – K3 Coating. Due to the Dragon Skin coating, their service life has significantly increased. The most popular models are Hi-Beam and Lo-Rider. In 2009, the brand introduced colored strings coated with a special luminous compound.

DR HI-BEAMS – Stainless Steel

- They don’t eat your Frets. Hi-beams are the string to choose for brightness, punch and ease of playing.

- Renowned for durability, unusually long life, consistency and string-to-string balance.

- Round wound and constructed on a round core, which is unique in the industry.

DR Black Beauties – Black Coated Strings 45-105

- Gauge: Medium.

- Hand-made with black polymer coat.

- Signature crisp tone, clarity, and volume of dr’s traditional handmade strings.

- Super-thin coating on the plain strings and on the wrap wire + extended string life.

Which Famous Bass Players Prefer DR Strings?

When the first bass strings went on sale, many people were skeptical about them. But with the approval of Marcus Miller and blues guitarist Jeff Healey, the company’s products quickly gained support in the music market. Sting, Stanley Clarke, and Bootsy Collins speak well of the advantages of bass strings produced by DR Strings. Blogger Marcelo Feldman aka “bass wizard” use DR strings in his bass arrangement videos as well.

La Bella

It is one of the oldest string manufacturing companies in the world. Today, it represents about 2,000 string types on the market, including those for orchestral and ethnic instruments.

Brand History

The company started its activity in 1640 in the Italian town of Salle. It was a family business whose owners were among the first to use manufacturing production. The company’s name was “House of Mary.” After a strong earthquake almost destroyed the town in 1913, brothers Emilio and Olinto Mari moved to the United States. They settled in Newburgh, New York, and opened a small store selling musical accessories. They also fulfilled orders for the production of strings. Their first factory opened in 1914. They named their company E. & O. Mari, Inc.

In 1918, the brothers decided to expand production capacity by building another string factory in their native Italian region of Abruzzi. In 1920, they developed the La Bella brand, which became the company’s flagship. In 1937, Emilio and Olinto hastened to close their business in Italy and fully transfer it to the United States. The reason for that was the approaching Second World War. Today, E. & O. Mari/La Bella’s only production site is in Newburgh. The president of the company is Olinto’s grandson, Richard Mari Jr.

In 1918, the brothers decided to expand production capacity by building another string factory in their native Italian region of Abruzzi. In 1920, they developed the La Bella brand, which became the company’s flagship. In 1937, Emilio and Olinto hastened to close their business in Italy and fully transfer it to the United States. The reason for that was the approaching Second World War. Today, E. & O. Mari/La Bella’s only production site is in Newburgh. The president of the company is Olinto’s grandson, Richard Mari Jr.

Technology

The company combined its forces with master lutenist James Carbonetti to produce the La Bella Strings bass strings. They decided to team up to create a series of handcrafted vintage basses. After years of creating state-of-the-art string instruments, La Bella has introduced a bass that embodies the vintage tone that has put the brand in demand. All the instrument parts, from the body to the strings, are made by hand.

The company uses bronze, copper, and nickel to wind bass strings. The most popular models are Deep Talkin’ Bass and White Nylon Tape Wound.

La Bella 760FS Deep Talkin’ Bass

- Stainless Steel Flat Wound Standard Long Scale Bass Guitar String

- String Gauges: .045, .065, .085, .105

- NOT suitable for basses with bridges that require strings to pass through the body of the instrument.

La Bella LTF-4A Low Tension Flats

- Best-selling light tension flat wound string on the market.

- Round cores for greater flexibility and narrower ribbon for an unrivaled smooth feeling Light Tension.

- Low Tension Flats deliver the same classic sound but without the floppy-string effect associated with other light tension flat wound strings.

- Made in the USA with American wire.

Which Bass Players Use La Bella Strings?

James Jameson, Donald “Duck” Dunn, and Bob Babbitt used La Bella flat-wound strings to achieve their legendary sound. Led Zeppelin bass player John Paul Jones preferred the Deep Talkin’ Bass models.

Every bass player will sooner or later decide what strings to choose. All the above companies are market leaders and have something to offer musicians.

Hey, fellow bassists and musicians overall!

I’m nothing more than just bass player and enthusiastic blogger. Feel free to ask any questions in the comments.

Huge thanks for all crazy people who supports this resource. Keep groovin’!